Fabric Analysis

U-values

Thermal Bridging

Condensation Risk

Façade/Fenestration Thermal Analysis

BFRC Energy Ratings

A ‘Fabric First’ Approach

Understanding the performance of the building fabric (also known as the building envelope) is key component in balancing the energy demand, plant sizing, optimising comfort and reducing risks of condensation, overheating and thermal stress.

As a logical extension, a ‘Fabric First’ approach can be employed to engineer designs for zero carbon and near zero energy homes.

Our services

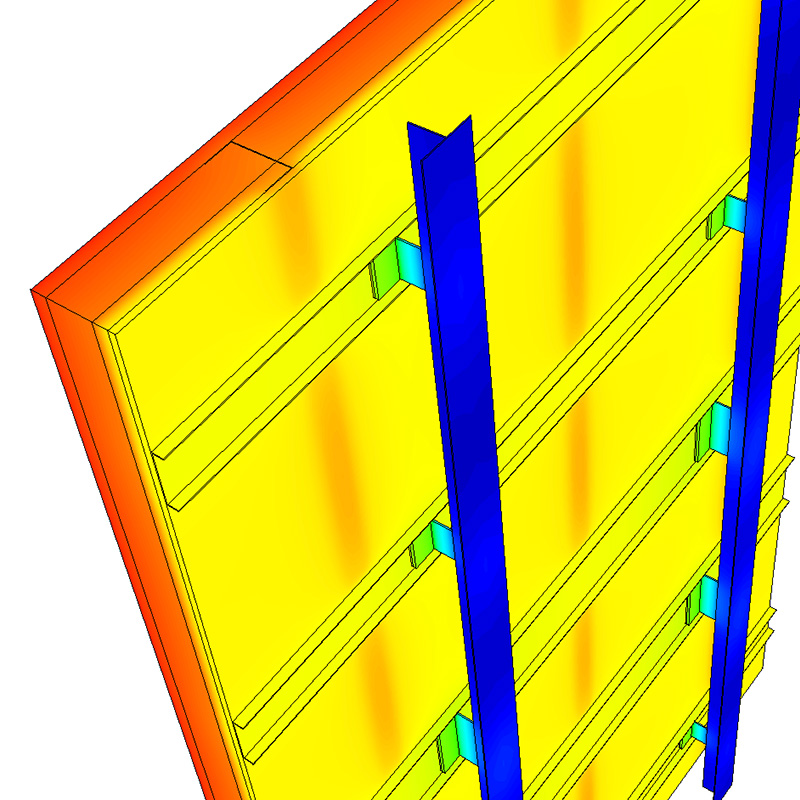

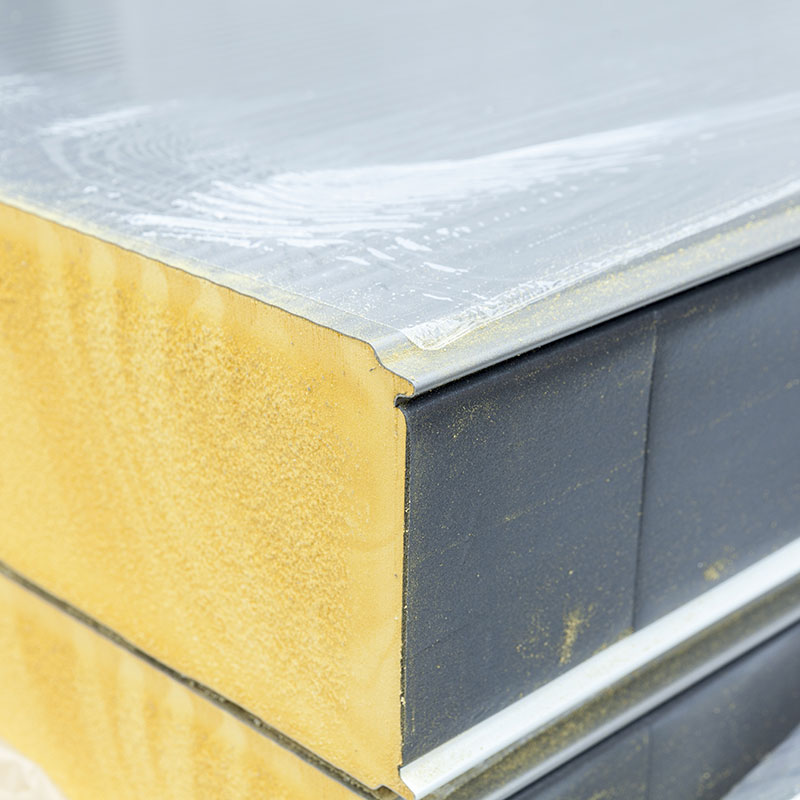

Rainscreen cladding channels, brackets and rails on steel frame substrate wall.

U-Values

For entry into SAP or SBEM it is necessary to demonstrate the thermal performance of building element walls, floors and roofs, characterised by the thermal transmittance, U-value. Components within these elements can be characterised by the thermal resistance, R-value. Our team undertakes analysis of element/component heat losses according to the guidance within BR 443: Conventions for U-value calculations as either:

- Simplified calculations in accordance with the ‘combined method’, as detailed in BS EN ISO 6946: Building components and building elements – Thermal resistance and thermal transmittance – Calculation methods;

- Detailed 2D or 3D thermal bridging calculations in accordance with BS EN 10211: Thermal bridges in building construction – Heat flows and surface temperatures – Detailed calculations;

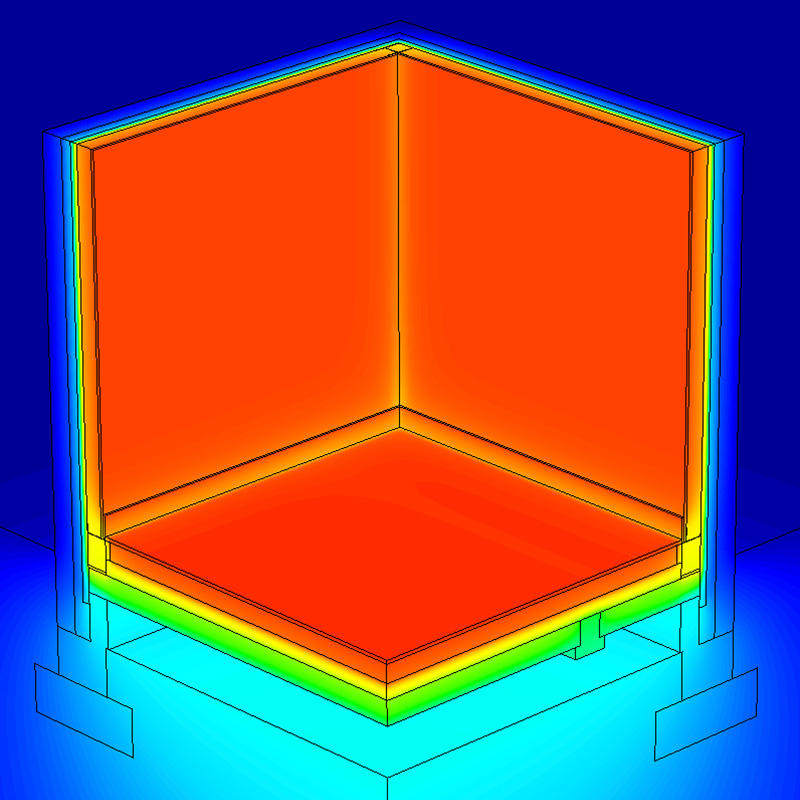

Ground Floor Junction Interfacing 3D Corner

Thermal Bridging

Junction thermal bridges account for between 15-30% of a building’s total heat loss. Through careful targeting, thermal bridging analysis of specific junction psi-values is an extremely cost-effective measure in reducing the building Y-value, attaining SAP and SBEM compliance, and can potentially lead to a lower build cost, reducing the need for costly to high specification glazing or renewables.

Our assessors are members of Elmhurst Energy’s ‘Psi-value Competency Scheme’ which is the UK’s only list of independently assessed competent persons in relation to thermal bridging analysis. Using our experience and the latest software (TRISCO or SOLIDO), we provide unrivalled consultancy and analysis of bespoke junction designs in accordance with BS EN 10211: Thermal bridges in building construction – Heat flows and surface temperatures – Detailed calculations, and BR 497: Conventions for calculating linear thermal transmittance and temperature factors.

Condensation Risk

Condensation forms on a surface when its temperature falls below the dew-point of the air which is adjacent to it. As moisture moves within building envelopes, cold surfaces may be encountered, potentially leading to:

- Surface condensation - on the internal building finish, leading to damp patches, mould growth, or corrosion;

- Interstitial condensation - within the hidden layers of the construction, potentially leading to pooling, or degradation of structural materials such as timber or metals;

Our assessors use their building physics expertise to assess designs, highlighting the potential risks and delivering consultancy to ensure those risks are designed-out. Depending on the complexity, we use a range of analyses, including:

- Thermal bridging surface condensation risk in accordance with BS EN 10211 Thermal bridges in building construction – Heat flows and surface temperatures, and BR 497: Conventions for calculating linear thermal transmittance and temperature factors;

- ‘Glaser method’ interstitial condensation risk in accordance with BS EN ISO 13788: Hygrothermal performance of building components and building elements – Internal surface temperature to avoid critical surface humidity and interstitial condensation – Calculation methods, and BS 5250: Code of practice for control of condensation in buildings;

- Dynamic surface and interstitial risk modelling using 1D or 2D WUFI software in accordance with BS EN 15026: Hygrothermal performance of building components and building elements – Assessment of moisture transfer by numerical simulation, and ASHRAE standard 160: Criteria for Moisture-Control Design Analysis in Buildings;

Façade/fenestration Thermal Analysis

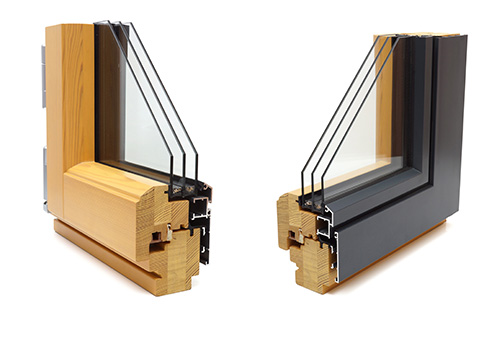

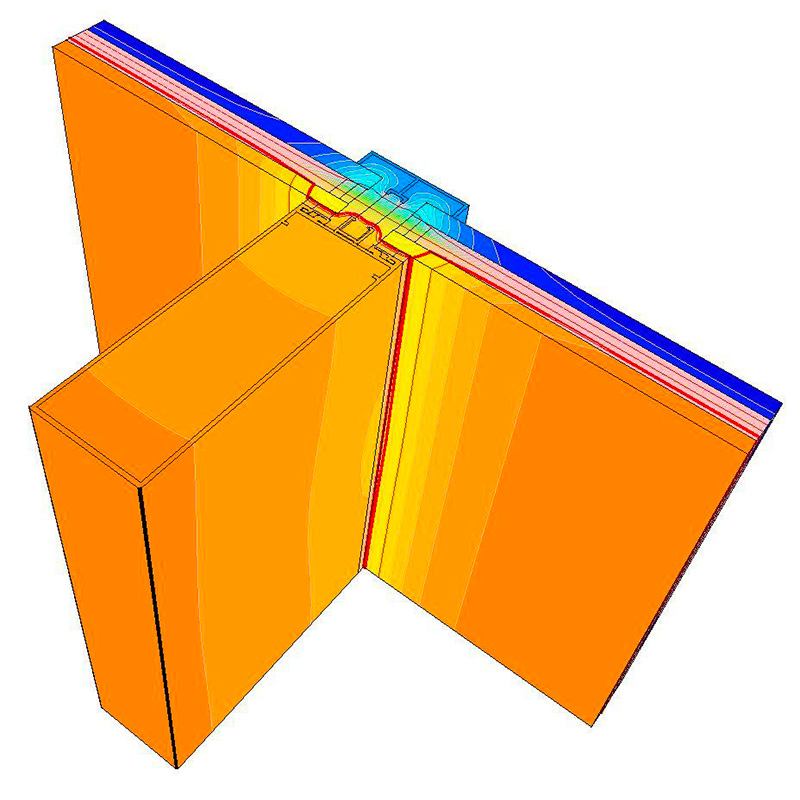

Curtain walling and fenestration products are key components in all building envelopes, allowing natural light and the sun’s energy to enter the space. The frame assemblies, panels and glazing within these products are complex thermal bridges which require precise 2D or 3D thermal analysis to characterise the heat flows, which can then be used to calculate overall U-values and risks of condensation [Link to ‘Condensation risk’ service].

Building NRG are members of the Curtain Walling and Cladding Technology (CWCT), while our assessors are accredited British Fenestration Rating Council (BFRC) simulators. We use our experience and the latest software, BISCO (2D) with the RADCON module (‘radiosity’ cavity method) and TRISCO (3D) to independently verify:

- Curtain walling U-values in accordance with BS EN ISO 12631: Thermal performance of curtain walling – Calculation of thermal transmittance;

- Window or door U-values in accordance with BS EN ISO 10077-1 and BS EN ISO 10077-2: Thermal performance of windows, doors and shutters – Calculation of thermal transmittance;

- Rooflight U-values in accordance with NARM NTD02: Assessment of thermal performance of out-of-plane rooflights, or BS EN 1873: Prefabricated accessories for roofing – Individual rooflights of plastic – Product specification and test methods;

- Risks of condensation in accordance with BS EN ISO 13788: Hygrothermal performance of building components and building elements – Internal surface temperature to avoid critical surface humidity and interstitial condensation – Calculation methods, and BS 5250: Code of practice for control of condensation in buildings or CWCT requirements;

BFRC energy ratings

British Fenestration Rating Council (BFRC) energy ratings utilises a UK specific energy balance rating equation, taking account of heat losses from U-value and air leakage, and heat gains via the glazing g-value.

Building NRG offer independent BFRC rating simulations for all types of fenestration products and we can guide you through the certification process.

Thermal Stress

Incident solar radiation on glazed panel assemblies such as glazed spandrel panels and shadowboxes can cause increased stress risks to the materials within, including:

- Glass: Partial shadowing can cause large temperature differentials within panes causing tensile stresses to potentially exceed the stress limits, causing the glass to fracture. Stress limits for glass can be increased through improved surface treatments.

- Gaskets, Sealants: In these materials the manufacturer’s recommended maximum temperatures can be exceeded, potentially leading to a compromised glazing unit, weather resistance or structural failure.

Building NRG use Physibel’s dynamic heat flow package, VOLTRA, to investigate 2D or 3D glazed constructions in accordance with DTU 39 P3. Our assessors can investigate perceived problems and make recommendations to eliminate risks.

Product Optimisation

With our many years of experience with thermal envelope building products, we can help you to develop your prototype or existing designs, in order to meet a specification (e.g. Passive House Component), or to ‘future proof’ them in relation to upcoming regulation. Through our advice you can improve performance, reduce costs, stay ahead of the competition, and be ready for third party certification.